Forum Replies Created

-

AuthorPosts

-

July 16, 2019 at 09:52 #26622

Chihili QParticipant

Chihili QParticipant July 16, 2019 at 09:51 #26621

July 16, 2019 at 09:51 #26621 Chihili QParticipant

Chihili QParticipant July 16, 2019 at 09:50 #26620

July 16, 2019 at 09:50 #26620 Chihili QParticipant

Chihili QParticipant July 16, 2019 at 09:50 #26619

July 16, 2019 at 09:50 #26619 Chihili QParticipant

Chihili QParticipant July 16, 2019 at 09:49 #26618

July 16, 2019 at 09:49 #26618 Chihili QParticipant

Chihili QParticipant July 16, 2019 at 09:48 #26617

July 16, 2019 at 09:48 #26617 Chihili QParticipant

Chihili QParticipantAh, here we go:

July 16, 2019 at 09:35 #26616

July 16, 2019 at 09:35 #26616 Chihili QParticipant

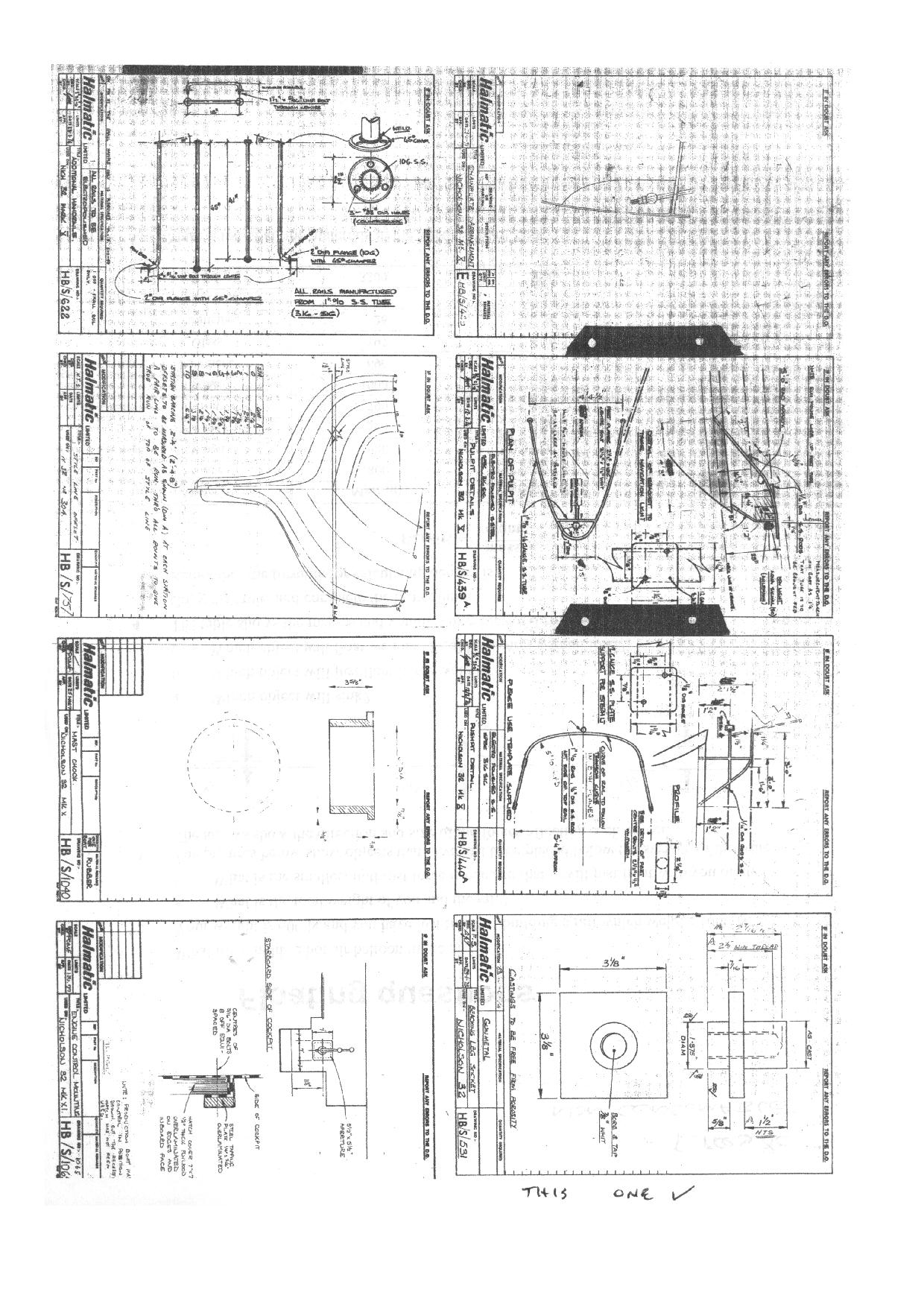

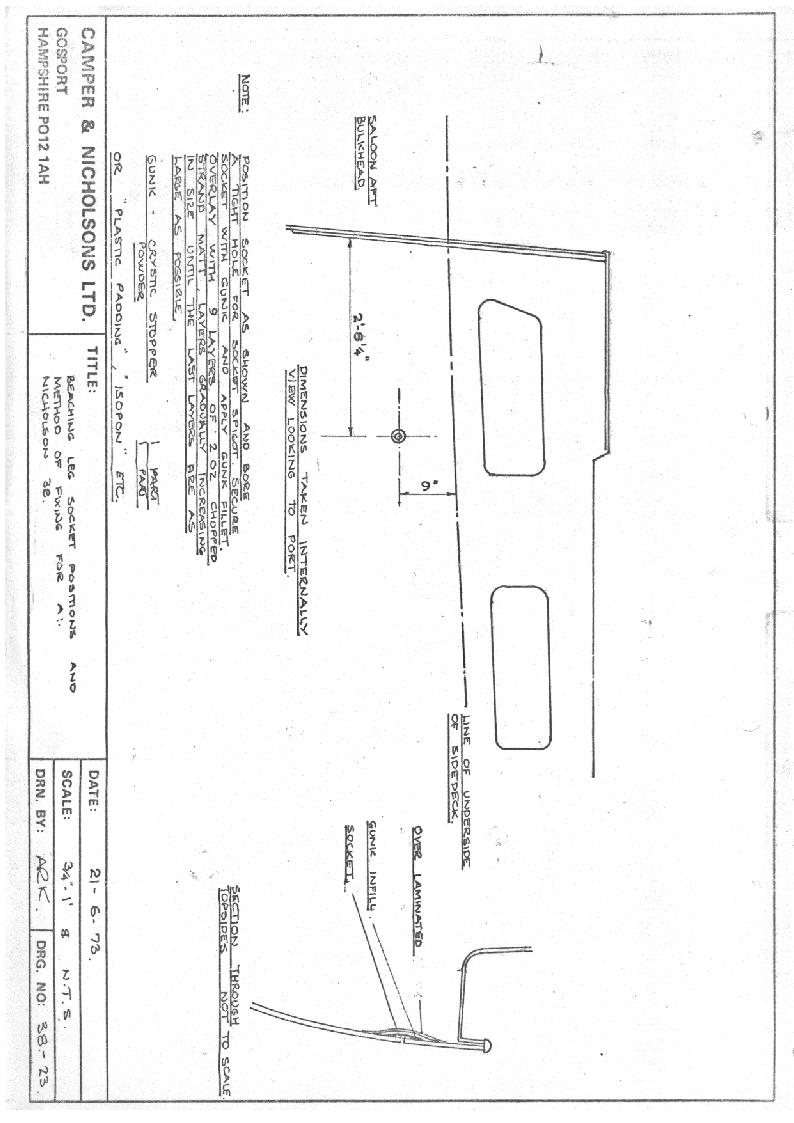

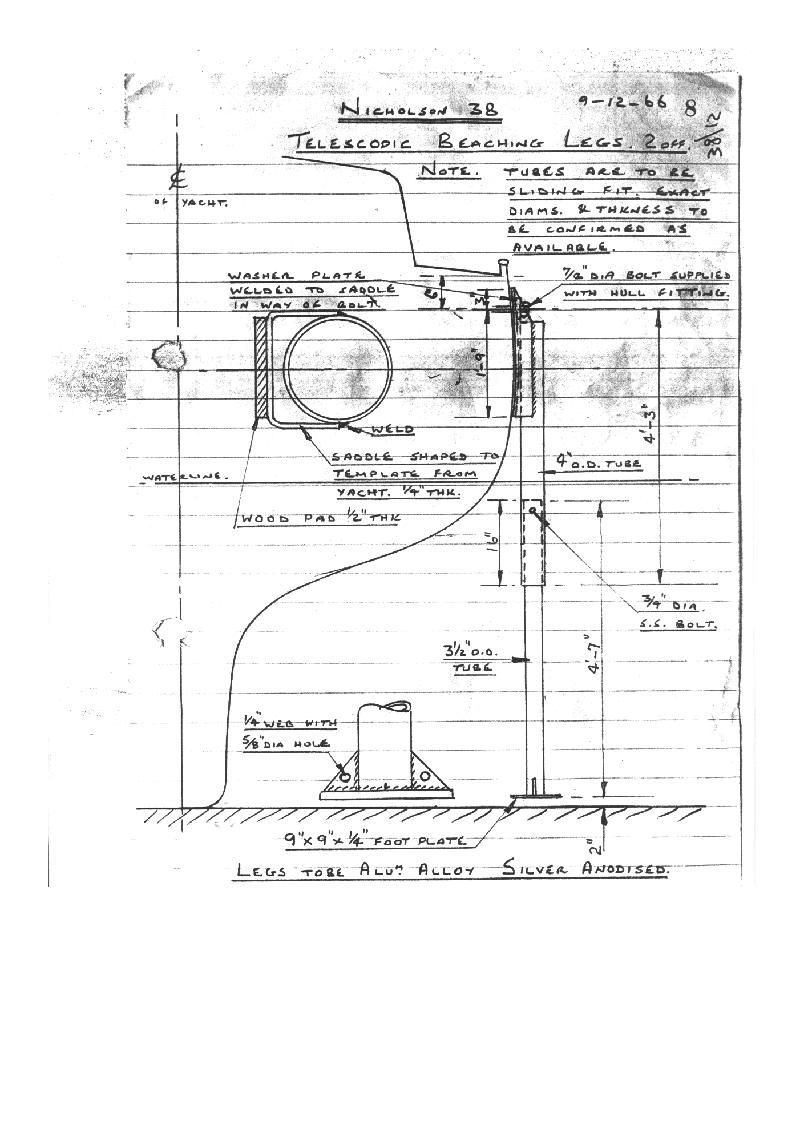

Chihili QParticipantSorry, not getting message alerts to my email account as previously, but Jeremy Lines sent me a note with quite a few details attached.. it is a 6 page document but although I have split it into separate jpg pages, I cannot post it here for some reason, I get a warning… if you email me on adrian-weston@hotmail.co.uk John I can let you have a copy. Regards, Adrian.

June 21, 2019 at 11:34 #26610 Chihili QParticipant

Chihili QParticipantIn fact, on reflection, I forgot that I had previously had the after deck sag corrected by a different boat-yard in Pwllheli, who put in a woefully inadequate glassfibre support with ribs running longlitudinally to add strength, whereas if anything these should have been transverse. Nothing like doing it yourself, which applies to any piece of work, on the boat or at home in my experience if you can be on site with appropriate tools etc! Except maybe I’m getting too scatter brained to do so anymore.

June 19, 2019 at 14:41 #26609 Chihili QParticipant

Chihili QParticipantHello all, I have not been reading posts for a couple of years partly since I have been so busy and partly since I don’t seem to be getting notifications into my inbox which may be due to Windows filtering out what it considers to be unwarranted contacts; anyway I’m still here.

I took Chihili Q to a Pwllheli boatyard after a trip in July 2017 expecting to sail her away the following September but she wasn’t ready until June 2018 during which time I was prevailed upon to pay half normal storage fees. Because I have now retired I plundered my pension pot and had new saloon windows fitted, the aft deck fixed, the hatches replaced along with her standing rigging and had her “Copper-coated”.

Yesterday I visited to try out some rubber shims for chocking the mast where it passes through the deck and was alarmed to find that she had filled up with (probably) rainwater to the engine bay. I have retained the cockpit drains but fitted one-way valves just before the through hull fittings (to prevent water refluxing up the pipes and slopping about in the cockpit) and I think it is these that are prone to block; consequently water finds its way into the bilge through the somewhat inadequate cockpit sole seals (otherwise it would eventually get through the doors of course). I had taken the batteries home to do a capacity test and consequently left her without the bilge pump switched on to automatic mode; were the cockpit draining directly into the bilge it would be crucial to leave the bilge pump connected to power and switched on auto permanently, and perhaps I should consider doing this anyway, or visiting often during rainy weather!

My insurer required Chihili Q to be surveyed a couple of years ago and the surveyor noted that I had put a one-way valve on the bilge pump outflow instead of contriving a high enough anti siphon loop in the pipe. We had nearly sunk soon after my purchasing her as a result of, what I later discovered to be voluminous siphoning back so I wasn’t too confident about relying on the loop system. The surveyor told me that the check valve was not sufficient and should not be relied on; he strongly advised reinstating a loop with an anti siphon valve in the loop; I have not yet taken this course but intend to do so. After yesterday’s little experience I’m glad to still have a boat to carry on improving indefinitely!

Best wishes to all, Adrian.

June 19, 2019 at 14:12 #26608 Chihili QParticipant

Chihili QParticipantLovely job Arild, I’ve been out of the loop for some time but have now retired and hope for a bit more time get my head round things! Last year Chihili Q was in Pwllheli until June for re-rigging and a bit of a refurbishment which included a fix to the sagging aft deck. The mahogany ply pad was rotten so this was replaced by glass and epoxy resin, along with replacement of the somewhat soggy transverse bulkhead supporting the deck, attention to the teak deck and stern locker, and a thick Iroko wood pad to spread the load between my gas lockers more evenly. I took her to Scotland and met a delightful couple in the new Oban marina who had just acquired a lovely, blue Nicholson 38; sadly as usual their names have disappeared from my contact list but I might have a record in my logbook. Anyway the skipper pointed out that in the original design of the Nic 38 the main mast’s backstay was originally attached to the mizzen mast giving it considerable support as he demonstrated on his boat! Chihili Q’s backstay is split and anchored to each side of the afterdeck, obscured in the photo by the training ship behind her. Best wishes, Adrian.

April 22, 2015 at 22:02 #25783 Chihili QParticipant

Chihili QParticipantmmm, try this:

.. no the image doesn’t copy.. I’ll try again soon. Perhaps I need Chrome!

Alternatively, email me Mike on adrian-weston@hotmail.co.uk and I can send pics direct?!

Adrian.

April 22, 2015 at 21:56 #25782 Chihili QParticipant

Chihili QParticipantHi Mike, hmpf, I wrote a piece but it doesn’t seem to have been posted, so sorry. I’ve run out of time tonight but this is the kit… no it’s not, I cannot figure out (having posted images to Flickr) how to post my pictures here yet. In short, the alternator would fit the Balmar MC-614 regulator like a glove; this has “small engine mode” to opt for 50% output from the regulator, and lots of other options. I shall be keeping the regulator to use with my Beta 43, Iskara 120 amp alternator. A potential problem with high output alternators is the need to ensure that wiring and fuses are up to spec. I hope to post again soon….

Regards, Adrian.

April 20, 2015 at 20:16 #25780 Chihili QParticipant

Chihili QParticipantMarilyn, that doesn’t look quite the same as mine but at present I cannot dig up photos for comparative purposes, I might just be looking at it the wrong way round; however, when I had the engine lifted a few years ago the raw water pump was replaced I think. If you email Nick Beard at Fowey Harbour Marine Engineers at nick@fhme.co.uk I am sure he can give you a more cogent answer. He said he would pull bits off and send on request (postage to US probably about £30-40 I expect??). Same applies to the lube system (it comprises a spin on filter, but the drain plug thread was a bit buggered up so I put another bolt in there which seems to work fine).

Regards, Adrian.

May 20, 2013 at 20:27 #13561 Chihili QParticipant

Chihili QParticipantA chap from East Coast Fibreglass Supplies says send in a bit of hull and he can do a colour chart check. Simples.

May 13, 2013 at 11:45 #13551 Chihili QParticipant

Chihili QParticipantI have no blisters, fortunately; Chihili Q was treated with International Paint Gelshield by her previous owner. However, my topsides have various scratches and one somewhat crazed area under her overhang from a minor impact, I presume. Previous repairs have been completed with varying shades of white gelcoat; is anyone able to advise whether all Nic 38 white yachts had some particular coded or named white tint? Mine was built in 1973 so presumably the archives might show this info?

Cheers, Adrian.

May 12, 2013 at 22:34 #13541 Chihili QParticipant

Chihili QParticipantLong overdue I have just installed an automatic float switch of the correct amperage, and another higher in the bilge with an alarm should water ever reach that level; these are mounted on a strip of aluminium which allows them to be lowered and fixed appropriately. A similar strip of aluminium (both present on my original purchase of Chihili Q) is welded onto a hoop of similar material, itself secured to a baseplate bolted onto the the strum box of a Rule 3700 bilge pump. This means that the bilge bump can be raised and sniffed, stroked or whatever.

I had wondered about replacing or servicing the pump, not knowing it’s true provenance, but a bloke at Safety Marine said not to worry, they don’t need servicing, “good for life”. Never-the-less, my new float switches required wiring and having done a radical job I tugged on the wire from the pump deep in the bilge, protected by “ducting” and found it almost severed through except for a few strands of copper. Oops, better replace the pump after all; in the event this ressembled delivering a baby and putting another one in it’s place: quite a challenge given my existing aluminium cradle/basket thing for holding the pump in place, but at least Chihili Q didn’t struggle or cry out. Afterwards I found another near break in the wiring where the Rule wiring had been connected to secondary wiring. Either of these connections could have “gone down” at any time. If my pump did fail to work, I would almost certainly have blamed my new wiring, not the pump and its immediate connections. Beware!

And watch out for so called “Marine” electricians; in my experience they employ household type electrician apprentices, judging by the materials and connections used, which can lead to all sorts of interesing surprises!

Cheers, Adrian.

May 12, 2013 at 21:52 #13531 Chihili QParticipant

Chihili QParticipantI’m puzzled.. I have a port to access the top of the rudder stock, and fit my emergency tiller with a square socket onto it’s suitably square profile. I have indeed had the stern deck lifted and reconstituted, but there was no need to do so in order to find the top of the rudder stock! Have you not got such a port?

Water was coming through my emergency access port since it didn’t have a seal when I purchased Chihili Q. But I now find the majority of water was actually coming through the delaminated timbers of my teak stern hatch, which probably contributed to the degradation of my aft deck as much as anything else, and going sideways then dripping down the aft cabin berth walls. I suspected this previously but obviously dealt with the problem inexpertly; later this year I intend to do something more radical, but as a temporary measure I have lined the edges of the laminated timbers forming the edge of my hatchway with wonderful modern roofing and building material: breathable but waterproof. Amazing, for the first time in 6 years or so, I have a rather dry aft locker!! What’s more, I have a dry aft cabin: water was pouring through the sole seams, and when I cut away the small sloping piece of flooring that abuts the locker bulkhead with opening access to the lower rudder stock I found the channel responsible for conducting water into the bilge absolutely crammed and blocked with debris of wonderful variety. Previously I thought I had cleared it with the odd poke of wire etc, but I am beginning to much prefer the radical remedy.

Regards, Adrian.

December 13, 2012 at 20:54 #12801 Chihili QParticipant

Chihili QParticipantGreat stuff. What a lure… hope to see you sometime during that week.

Adrian.

November 21, 2012 at 11:05 #12621 Chihili QParticipant

Chihili QParticipantInteresting; I wondered what you were on about referring to wing tanks; my fuel tank is under the companionway steps, my cockpit lockers are gaping caverns without partitions; a bit wet for sails really but I hope to remedy that in time. This space in Ronar’s locker might be begging a heat exchanger if you haven’t installed one already; I haven’t but it’s on my wishlist. What an amazing variety of modifications we see posted!

BW, Adrian.

November 21, 2012 at 10:54 #12611 Chihili QParticipant

Chihili QParticipantHere’s another link, not sure how comprehensive their range is but good so far:

http://parts4engines.com/index.php?main_page=index&cPath=39

Regards,

Adrian.

April 23, 2012 at 13:04 #11491 Chihili QParticipant

Chihili QParticipantThis is probably similar to the Sikaflex which I have used, which also requires a primer for the teak. I spoke to a chap in Aberystwyth who is a joiner and owns a Thai 40 footer whose teak deck had been removed; he is replacing this with Keroin (which in my very limited experience is prone to splinter) and he strongly advocates window black mastic for caulking. Hell of a lot cheaper but I wonder if this will prove to be a false economy! Sikaflex is not so soft and to avoid it separating from the wood needs a release tape putting in the bottom of the gap so it only needs to stretch in 2 dimensions.

March 17, 2012 at 20:55 #11351 Chihili QParticipant

Chihili QParticipantChihilli II is now Chihilli Q and indeed she has extended masts (both just now reinstated with new wiring which had turned to dust apparently) so I imagine my spinnaker and crusing chute dimensions are of little use to anybody else.

March 17, 2012 at 20:50 #11341 Chihili QParticipant

Chihili QParticipantThe yard tells me that the wooden packing wedges supplied with the kit is not sufficient and has had to be supplemented with some additional packing material. Otherwise installation is reportedly complete, and the boat ready for sailing away.

February 23, 2012 at 20:44 #11281 Chihili QParticipant

Chihili QParticipantI am expecting delivery of one tomorrow at the boat yard! However that is a long way off and I don’t expect to vist for a few weeks; Hydrovane have hopefully sent all the right spec stuff based on their previous experience and fittings. They seem extremely helpful if you deal with them directly and no doubt would tell any specifics you request. They have supplied me with Hydrovane model VXA2D M (shaft length)/H/E and standard vane and wrote:

“Please review our website at http://www.hydrovane.com/index.htm – in particular the SPECIFICATIONS and PARTS tabs/sections to see the three types of brackets. You will need two brackets:

• Upper – a hinged ‘H’

• Lower – a single strut ‘E’ – which strut you will cut to size.SHAFT LENGTH – Our shafts have standard lengths that vary in 10 inch/25 cm. increments. For your boat we suggest an ‘M’ shaft – will put the base of the Drive Unit at 110cm. above the water. The determinants in the shaft length decision are generally to put the Drive Unit at the height that is easiest for operating. Other limiting factors such as arches and mizzens might enter into the equation. Often our bias is towards the shortest version that would suit your boat – as it is cheaper. If there are no other aerial obstructions the next longer size would also be equally suitable – actually superior as there is more wind the higher the vane can reach. If you would like that potentially extra bit of performance you can ask Will if it would work for your boat”.

Regards, Adrian.

January 21, 2012 at 12:40 #11091 Chihili QParticipant

Chihili QParticipantMany thanks indeed Trevor for that. I have discussed things with the yard and we are going to adopt Roger’s solution regarding a deck fixture; for reinforcement I am going to have a SS plate on the outside of the stem and moulded to the hull shape; my main reason for doing it this way is that since Chihili Q collided with the pontoon (engineer taking her back to her berth after reinstallation of the engine, and with wonky morse control: full astern turned out to be full ahead)there is a visible repair at the level such a plate would need to be; I am not installing armour plating though! There will be a through hull anchor point with eye to attach a dyneema brace to the underside of the deck fitting. Seems an excellent solution, and a variation on both your suggestions.

BW, Adrian.

-

AuthorPosts