Forum Replies Created

-

AuthorPosts

-

August 18, 2020 at 22:45 #26733

Nicholas Fairhust

ParticipantGraeme,

If you are looking for a Nic 38 friendly boatyard near Oban with swinging moorings and winter laying up I can recommend Balvicar Boatyard:

Address:

Balvicar, Oban PA34 4TE, United Kingdom

Phone: +44 1852 300557Good clay holding ground, easy access to Cuan Sound and the Lynn of Lorn, good winter storm protection but insurance will need the masts removed when laid up ashore…

Nick

May 30, 2020 at 14:18 #26708Nicholas Fairhust

ParticipantGood morning Kris,

Our school has been building a sailing skiff, now completed. The small craft instructor David has shown a lot of interest in my Nic 38, Rampant’s ,restoration and expressed an interest in cruising with his young family on the East coast….He and his family might well be a great “next custodian” for your vessel, he certainly has the skill sets needed ?

Drop me a line and I will put you in touch and see how it goes ?

Kind regards,

Nick

May 29, 2019 at 23:10 #26590Nicholas Fairhust

ParticipantGood to hear from you Van,

I am 100% with you on a permanently flexible bedding compound for all the reasons you mentioned. As a young apprentice marine draughtsman in the 60’s (Toughs of Teddington, London) I was hauled over the coals by the yard foreman for specifying one of the then new fangled polysulfide sealant / adhesives. His main concern was that even if there was the correct thickness to give an even gasket by not over torquing fasteners the labor needed to remove the hardware was increased by a factor of three and difficult to justify to the vessels owner… Marine windows / port-lights and hatches in particular.

Ease of shroud plate inspection has been facilitated by removing all the interior doors and seat / bunk hatches. However, even if all the S/S components look good on close inspection there might still be micro fissures, older nuts are particularly prone ! On this note S/S wire guard rails are prone to unexpectedly fail at the swaging and even with careful, regular checking crevice corrosion / breakdown is hard to detect. Personally, I replace it every five years if I can, as I am with Rampant.

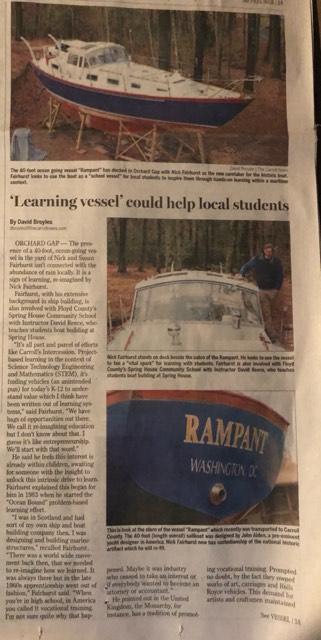

As for a photo. Attached is a local newspaper, front page, ( not many ocean going ketches on the mountain) article. The photo is taken from my office window so it is also my daily view – what more could I ask… The learning component refers to a high school boatbuilding program I am involved with.

Toodle pip & kindest regards to Marilyn.

Nick & Susan

April 20, 2019 at 22:03 #26577

April 20, 2019 at 22:03 #26577Nicholas Fairhust

ParticipantEvening John,

Sound advise, thank you… With full cockpit side curtains very little rain water gets in whilst at anchor or at dock. Underway, best practice is to close the cockpit seacocks so it looks as if we will be following suite with you and Robin.Very pleases SYH and C&C were able to help find a new custodian for Voltair – great team there and good access for UK east coast cruising. Happy memories for the family, particularly of Waldringfield sailing club.

TTFN

March 5, 2019 at 02:59 #26556Nicholas Fairhust

ParticipantThank you Van,

No 53 is now safely shored up outside my workshop at Book House, elevation 3,000 feet – the views from the aft deck are 50+ miles on a clear day…

All removable interior doors,panels,shelves and sole boards are now removed and in dry storage. This has given me a clear line of sight for the wiring, plumbing, gas lines, tankage etc and as to what is located where and how, in order for me to draw up some schematics for future reference.

The interior headlines are down in order to check for any deck hardware leaks and I am happy to report only one leak was evident on hose testing and now remedied. The bilges and hull interior have been cleaned and some areas reinforced with laminated gussets where the starboard saloon U berth/seating were lightly tabbed in, for extra rigidity on the turn of the bilge. 50% of the bilges are painted out whilst we had a warm spell and all the seacocks dismantled, serviced and new ABYC hose fitted where needed when it was too cold.As John commented, a audit of all the electrical systems has been the largest task but I am pleased to say the excellent installation and quality of fittings from the 2011/12 refit have minimized the damage to the wiring looms and terminals.I am working my way through the electrical equipment but the long term prognosis for most of it is not good – as one would expect.

As I work systematically through the vessel I have not yet found a ” smoking gun” as it were.You mentioned the prop shaft stern gland, plenty of greasy packing in evidence and no appreciable play in the shaft.I will fit lock nuts and a remote grease cup but otherwise all good. In my professional experience a number of conspiring mechanical/ physical coincidences can result in a vessels bilge pumping system becoming over whelmed and my instinct leads me to this conclusion with #53 – but as life teaches us we can never relax on keeping our eyes and ears open… Murphy is a hard taskmaster !

Will keep you posted and enjoy your on board projects – did you get snow 🙂

Nick

March 5, 2019 at 01:57 #26555Nicholas Fairhust

ParticipantEvening Marilyn,

Looking at your photo it looks as if the skin fitting is most likely 1″ OD as the valve assembly has what looks like a 1″ OD bib connecting it to the old pattern Groco filter body on which you have the 1″ outlet stepped up to a 1 -1/2″ OD feed.. The important dimension for your engine cooling is the ID or inside diameter of the smallest aperture in the feed system to the engine ! The engine specs will advise you of this particularly for tropical waters. I concur with your plastic bag scenario but check that you do not have a filter rose or grid on the outboard side of the skin fitting / through hull as they were sometime fitted to engine inlets – you might put your cleaning rod through it whilst dodging the water spout ? The old Groco SV filter body and valve are really well made and difficult to better now – why not give it a good check over on haul out and recondition it with new bolts and gasket if it is as good as it looks ?

Rampant is 30% through her refit and looking even more beautiful than ever – even made it onto the front page of the local newspaper (we do not get many blue water ketches up here on the mountain)….

Nick & # 53

November 23, 2018 at 20:59 #26489Nicholas Fairhust

ParticipantGood evening Charles and fellow Nic 38 custodians,

This happy conclusion to a sad event and how a really good organization with a wonderful person at it’s head can facilitate and perpetuate the enjoyment and learning that truly great vessels can help embody, in ourselves and our families, has been in evidence here.

Our family circle covers the Pacific Northwest, the Scottish Highlands & Islands and the Atlantic seaboard of the United States so some of the best cruising grounds are open to to us and Rampant, aptly named when the Lion Rampant is the heraldic emblem for Scotland, protocols allowing…

Once 100% seaworthy again #53 and our family at large will, I am sure, be renewing old and new cruising acquaintances from the ranks of this owners club and the great vessels that bring us together.

I think Jeremy would be happy that his design team had helped facilitate a line of vessels that have establish a healthy global family cruising mindset in so many.

Nick & the family Fairhurst

November 16, 2018 at 01:53 #26486Nicholas Fairhust

ParticipantEvening Rodger,

Sadly there is no easy answer but it is the beginning of the haul out and laying up season so RP might now be on the hard ? As with you trying to squeeze my old bones into tight spots and then extricating myself is becoming harder by the day !

My solution for one such valve on #53 is to move the valve and reposition it once I have taken it into my workshop and stripped down & fitted 4 new Blakes through bolts, 2 flange machine screws after having lapped in the tapered valve faces – I also use their grease which seems to last longer.. That’s the easy part, if you have access to a grinder and a good face mask / goggles. The next part is more difficult and I would leave it to your local boatyard laminator (but I would specify West products and laminating protocol). Laminating the old positions hole is not difficult but it does require experience and a thorough knowledge of the preparation of the interior and exterior hull surfaces along with the use of the epoxy laminating process and curing requirements ! A good laminator set up ready to do the repair should take about three hours for the process, up to and including fairing off with peel ply, leaving you to sand and perhaps apply some Gel Shield before your overall antifoul coatings.

Repositioning the rebuilt valve and installing it is not so hard with “reasonable” skill sets, the inboard backing pad needs some careful shaping and sealing if you use BS 1088 marine ply. Some racers like a flush out board face for the four domed bolt heads and backing plate but for us cruisers seeing them standing proud is like a badge of honour 🙂 Again a good underwater sealant is worth the extra money but in the “old days” they used Sealastic and putty mixed together and it worked just as well plus easy to remove again at a later date… Over the years I have come to understand that there is no ideal place to reposition a seacock – it always involves a compromise but ease of operation and for servicing should be at the top of the list. One other point, if you are a skinflint like me, the old style seacocks and bodies can be serviced and kept going ad infinitum so long as there is no electrolysis (carrotty orange colouring). The new range include a grease nipple, again if you have good access, makes lubricating easier, so you might want to buy a new version and sell the old one on EBay as they seem to sell for silly money !!

There is a really good series of U Tube Classic Yacht videos by Suffolk Yacht Harbour UK, where Mick shows and tells you a bit about the subject: http://www.utube.com/watch?v=BFU2tJDCJDY (this post does not let you copy and paste) SYH are also Nic 38 friendly if you find yourself on the UK East coast.

Hope this helps and in my opinion the Blakes seacock has no peers, so stick with it.

Nick Fairhurst

November 16, 2018 at 00:31 #26485Nicholas Fairhust

ParticipantA lovely person, only met him once but his sense of duty and service was very strong. An inspiration to us all, his passing over the bar leaves a gap that will be hard to fill and gives us an opportunity to pause and reflect how we as a community could best remember and pay back his kindness and support?

N 15 /11 /18

November 14, 2018 at 01:15 #26482Nicholas Fairhust

ParticipantThank you Marilyn & good evening from the mountains of Virginia,

This is an overview of my passage into Nic 38 custodianship. As a young apprentice marine draughtsman with a competing firm of C&N, I was very taken with the Alden based lines of the Halmatic hull, from whom we also purchased bare hulls in the 60’s & 70’s. This initial impression stayed with me throughout my career, to be reinforced by seeing and visiting Nic 38’s in the Highlands & Islands and English East coast whilst cruising. On retirement from the UK to the mountains of VA, I naturally contacted this esteemed owners club in 2015 to enquire about any vessels that might be in need of a new, sympathetic custodian.

On reading in this column several months ago about hull #53 “Rampant” taking a brief bath at her Maryland berth, I set out to talk to her long-term owner. As is often the case with good well-found vessels, #53 had found her way into good family hands since the early seventies with a major refit in 2011 & 2012. Being of undoubted pedigree, good bones, and continuous professional maintenance, my decision to ascertain if my family and I were a good match to the expectations of her owners was met by them with great enthusiasm and I have to say a wonderful sense of accord. In this vein #53 has now found a new family to get her back to 100% seaworthiness and to be cruised & cherished for another forty or so years in US and UK waters.

SEACOCKS POSTSCRIPT

As a now retired marine professional, I have often been asked why vessels sink, to this end admiralty attorneys, marine surveyors, and “expert witnesses” make considerable fees in trying to find an answer that underwriters would like determined. My comment on this, and it is no reflection on what happened to #53, is what should we as responsible seafarers do to take reasonable precautions in preventing such mishaps occuring in the first place? Familiarizing yourself and your crew with the location, maintenance and consistent use of all the seacocks, particularly when the vessel is left unattended, is paramount in preventing a high proportion of flooding incidents. Seized, poorly located or the incorrect specification seacock needs remedial action as soon as possible. Time and money should not be spared on the grade and ease of location for seacocks and if necessary, extension rods fitted in the case of inaccessible valves as well as the use of a pre/after sail check off list showing valves open or closed. Good quality valves, properly serviced should be easy to use, some such as the Blakes WC inlet/outlet require some understanding as to how they work and need to be set up and lubricated accordingly. All said and done these observations will help me sleep soundly in my bed at home knowing I have at least done all I can to prevent any flooding via the seacocks – ah! but what about that dripping stern gland….

Fair winds and a following seas to all.

-

AuthorPosts